Blu Putnam and Erik Norland, CME Group

AT A GLANCE

- Just-in-time delivery works well when an integrated global economy is functioning smoothly with few barriers to trade

- Both companies and governments are making strong moves to diversify supply chains but it’s a complicated and long process that may take years. In the short term, the world’s logistical issues might grow worse

Just-in-time delivery – in which a manufacturer receives raw materials and begins production only when an order is placed – has dominated supply chain management for decades.

But recently, the logistics of that model have increasingly been tested by global challenges, including tariffs and sanctions, the COVID-19 pandemic, Russia’s invasion of Ukraine, and more.

To get some perspective on what this could mean for both companies and consumers in the days and years ahead, let’s start with some background on the supply chain strategy under pressure.

The Origins of Just-In-Time Delivery

In the decades following the Second World War, Japan grew tremendously. There were many reasons for this growth, among them the innovation of just-in-time delivery. After the war, cash-constrained Japanese companies couldn’t finance the acquisition of large inventories of commodities and component parts as easily as their American counterparts. As a result, they pioneered lean manufacturing that made the most efficient possible use of capital, buying only the inputs they needed and getting those inventories there at just the right moment. By the 1980s, Japan had world-beating manufacturing that spanned automobiles to electronics.And by the 1990s, this just-in-time, lean manufacturing ethos spread worldwide. With the collapse of the Soviet Union, the integration of China into the global economy, and GATT agreements that reduced tariffs, barriers to trade seemed a thing of the past; just-in-time manufacturing went worldwide, helping to keep a lid on inflation. Everything seemed to move along fairly smoothly until the past two years, but now the world is beset by logistical problems all along the supply chain. So, what went wrong with just-in-time delivery?

The Challenges of Just-In-Time Delivery

Just-in-time delivery works well when an integrated global economy is functioning smoothly with few barriers to trade. However, over the past few years, the assumptions underlying lean manufacturing have been severely challenged for several reasons.- Even before the pandemic struck, there was some movement toward diversification of supply lines stemming from the Sino-U.S. trade dispute in 2018.

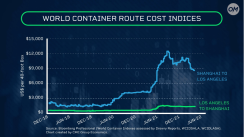

- In 2020, COVID lockdowns began to create severe supply chain disruptions.

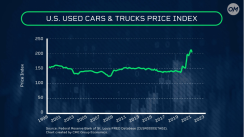

- At the same time, consumer spending shifted away from services toward manufactured goods, and demand for manufactured items began to outstrip the global economy’s ability to produce them.

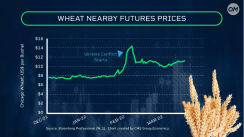

- Finally, in 2022, renewed COVID lockdowns in China deepened the world’s logistical challenges for manufactured goods at the same time as Russia’s invasion of Ukraine disrupted the supplies of key commodities.

The Outlook of Just-In-Time Delivery

Both companies and governments are making strong moves to diversify supply chains but it’s a complicated and long process that may take years. In the short term, the world’s logistical issues might grow worse. China appears to be favoring a strategy of zero COVID over economic growth, which has global implications for the manufacturing and consumer product sectors. Meanwhile, the impact of the Russo-Ukrainian conflict on the commodity markets is just beginning to be felt.

Ultimately, consumers are likely to experience the world’s logistical challenges in the form of higher prices for manufactured goods, and companies may see reduced profit margins as input costs climb and they find it more challenging to get products to market. Just-in-time won’t disappear but making supply chains more resilient will likely come with increased costs.

Read more articles like this at OpenMarkets